EASY INSTALLATION WITHOUT ADDITIONAL HYDRAULICS

TMK Tree Shear’s attachments do not require any additional hydraulics; all functions can be operated with a single, two-way hydraulics circuit. All our attachments have been designed so that they can also be retrofitted easily.

Excavator attachments often require complex installation and extra parts to function properly. We at TMK, on the other hand, wanted to develop attachments that are easily exchanged from one machine to another, and can also be installed on other machinery, such as a harvester, log loader or agricultural tractor. The easy installation enables you to choose exactly the equipment you need.

Globally, TMK ’s range of attachments is by far the most comprehensive compared to other tree shears.

TMK Tree Shear attachments: watch the video and learn about our product selection

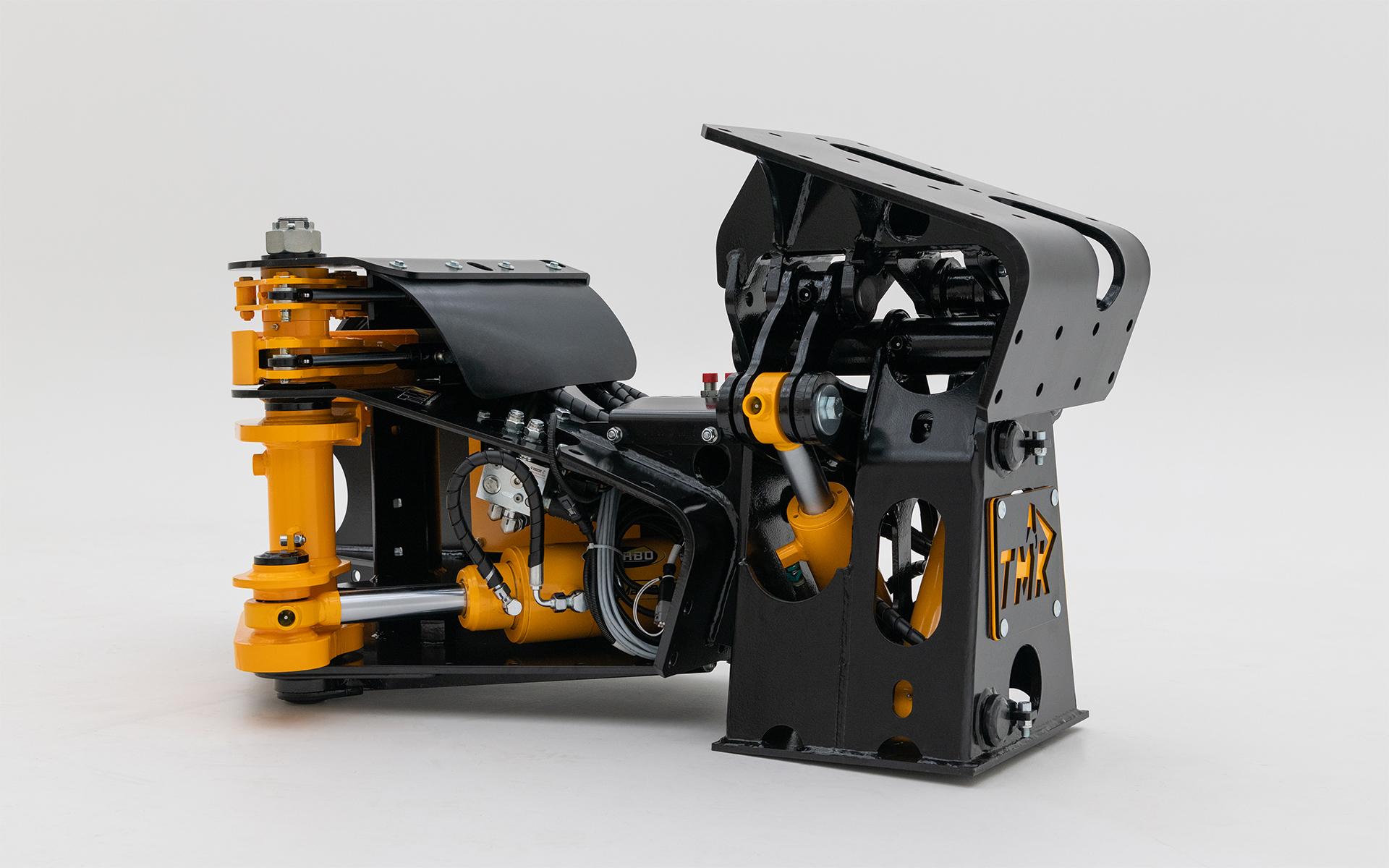

Collector’s been our most popular attachment worldwide for years! It was time for some improvements, so we designed the Collector Gen2.

The simple operation of the Collector enables quick and easy operation, for example when thinning a young forest. With the Collector, you can cut and collect thin trunks without having to lift the boom after each cut, turn the machine and drop a small trunk into a pile individually. This means you can minimize functions that consume fuel, and instead use the full capacity of the shear to make a bundle of trees. Thanks to TMK Tree Shear’s innovative valve packages, you don’t need separate hydraulics for the Collector. All functions of the shear work with just one double acting hydraulic line.

All the mechanical parts have been reinforced and the forest working conditions have been considered while developing the improvements. Collector spring and arms bronze bearings are now more easily accessible and faster to replace, with the addition of easier access to the grease points.

Due to the geometry improvements the Collector will now open with a deeper motion. This will make it more efficient even with larger diameter and branchier trees, improving the accumulating capabilities.

Along with the new mechanical parts, we’ve also produced two alternative control methods for the Collector. Easy & Full Control.

Easy Control:

The Collector works automatically alongside the cutting motion of the Tree Shear. This means that every time the grapple is closed to cut a tree, once the grapple is fully in, the Collector opens automatically to collect the tree, hence the “easy control”. Through controlling the Collector this way, we can achieve high speeds and efficiency especially when working with a lot of smaller trees.

Full Control:

The Collector works completely manually, only opening when the connected electric button is pressed. As its name suggests, this gives the operator full control of the Collector movement, eliminating extra movements, improving fuel efficiency, reducing oil heating on bigger trees and continous usage and reducing the wear and tear of the mechanical parts. Also in the case of any operation errors or malfunctions of the Collector, the work can continue, as the Collector is manually controlled.

Collector Gen2 is availabe for TMK 200, TMK 250, TMK 300 and TMK 400.

Planning on getting a shear with delimber function? The TMK Tree Shear Delimber enables optimal use of energy wood. Demand is high in the Nordic countries for trimmed timber, making the Delimber a really popular attachment. The delimbing tree shear, or energy wood grapple if you like, makes your work significantly more efficient.

Why would you get a separate trimming machine if the alternative is a cost-effective product package? When you get a TMK Tree Shear Delimber, you can trim your timber with your existing machinery.

The Delimber operates on a very simple principle: you take the tree shear at the base of the tree and grab it between the Delimber and grapple. Delimbing the tree is fluent thanks to the diamond-shaped slot where the tree trunk is held in place. The diamond shape in the same direction as the machine allows for a certain amount of freedom as to the position of the shear relative to the tree. This creates a smooth movement, making delimbing faster and simpler without great danger of the tree snapping in half during the process.

It is crucial in delimbing that the bark is broken, because it speeds up the drying process. The TMK Tree Shear delimber scrapes the bark and surface at best simultaneously from three sides, making it dry much more quickly. When trees are delimbed when cut, the trunks thaw more quickly in the spring, and they are easier to handle. This also increases the timber’s calorific value.

The Delimber can be attached to all TMK Tree Shear models. The Delimber works without rolls or pulses. It can also be installed to operate without electricity, and it is easy to retrofit on the shear.

With the TMK Tree Shear BrushGrapple, you can cut even the smallest trees neatly. An additional blade welded at the bottom of the grapple is sharpened on one side only, and it eliminates the gap between the grapple and the blade. As a result, the cutting motion becomes more scissor-like and even the most flexible twigs, such as small willows, are cut cleanly. The wood chipper stays in better condition, too, when no extra soil and stones are brought into it.

The BrushGrapple is such an essential attachment that most of our shears are sold with it.

TMK Tree Shear’s Solid Extension provides extra safety when working in difficult locations and when dealing with problem trees. Moreover, it makes the clearing of field edges easier. The Solid Extension connected to a tiltrotator enables you to cut down a tree round an obstacle without having to move the machine.

The Solid Extension (or fixed extension or mechanical extension beam) is an excellent attachment especially with a Delimber, because it speeds up work and makes it more cost-effective. The Solid Extension adds about a metre (3 feet) of extra reach.

The Solid Extension was designed specifically to be used with a tiltrotator, because it enables you to keep the rotator’s sensible hoses at a safe distance from the branches, thereby minimising damage to them.

The Solid Extension is also available with claws and a heel as a standard attachment, making it easier to move the machine in difficult terrain. The additional claws can help you to for example pull up small tree stumps

The Solid Extension is available in two sizes: A smaller, lighter model that fits the TMK 200, and one that fits the TMK 300 and TMK 400. Thanks to the fitting plate secured with bolts, the Solid Extension can be removed with ease if it is not suited for the work at hand.

A Hanging Tilt is an excellent attachment when you need to equip an agricultural loader or harvester for forest thinning. The Hanging Tilt has a turning radius of more than 165 degrees, guaranteeing a good range of motion. The sufficiently small cylinder ensures that the tilt moves quickly.

The Hanging Tilt is a particular favourite of tractor contractors. If you are already familiar with a timber loader, the Hanging Tilt enables you to continue the same way of operating when using the TMK Tree Shear.

The Hanging Tilt is connected to the rotator, so it operates on the same principle as other forest trailer attachments. Thanks to the rotation, it is also easy to load directly into the trailer. However, when the TMK Tree Shear is hanging freely, many of its good properties are not available, making delimbing especially much more difficult.

TMK Tree Shear’s Adapter Linkage adds versatility and speed to the unit. The Adapter Linkage was designed to speed up work when using a Hydraulic Extension, but it can also be used on machines that are unable to tilt the tree shear.

The Adapter Linkage has a turning radius of more than 180 degrees, guaranteeing a good range of motion. The sufficiently small cylinder ensures speedy operation. The Adapter Linkage is attached to the tree shear with bolts, meaning it is quick to put on and take off, and the shear can also be used with an excavator.

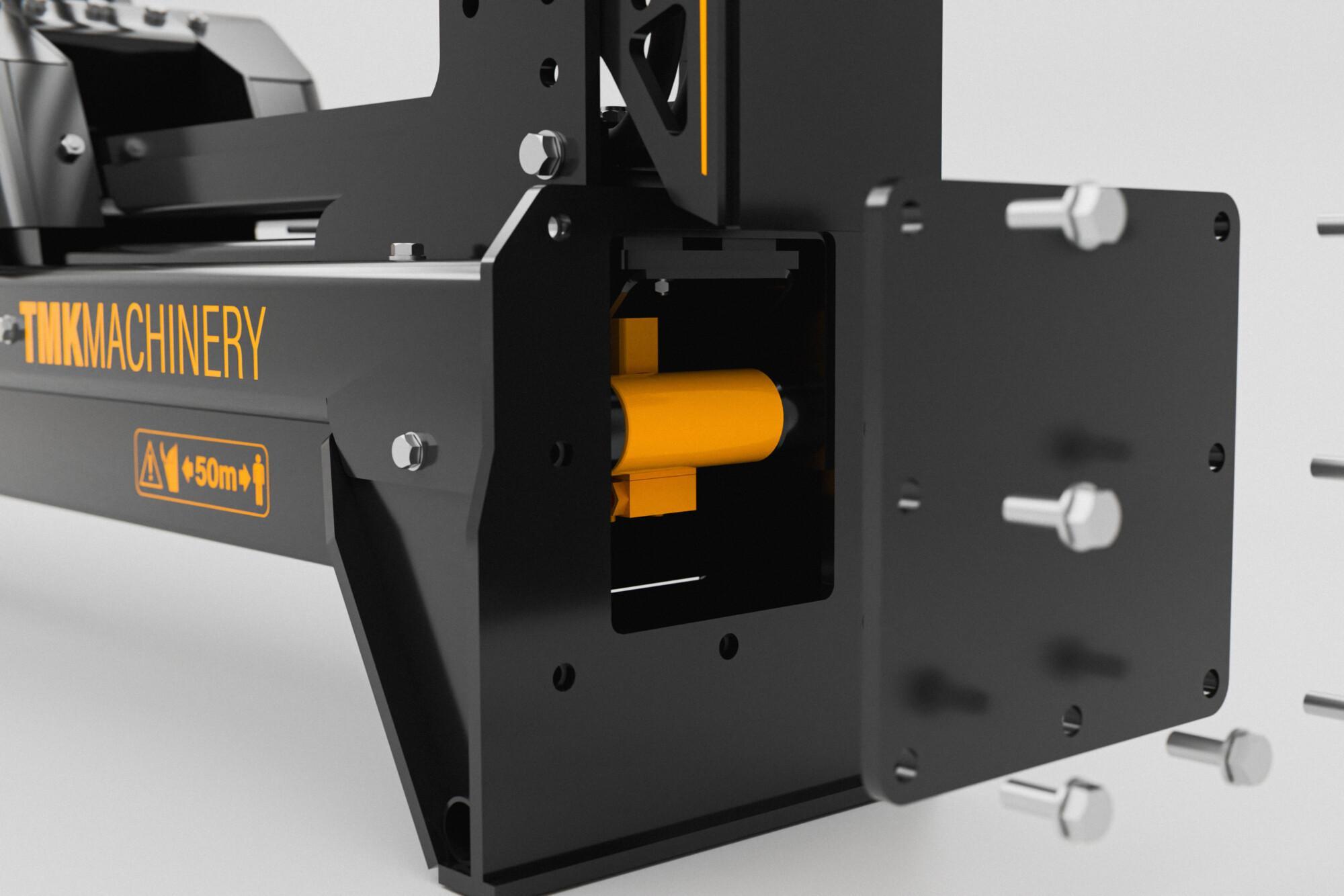

The Hydraulic Extension Gen2 gives you the extra reach when you most need it while still being able to move in small places, cut close to the machine and take support from the ground when going over ditches and bad terrain!

Our second-generation Hydraulic Extension gives you:

1,6 Meters of hydraulically operated reach. Total extra reach is about 3 meters all the way open depending on bracket used.

165-degree tilt unit on the Tree Shear at the end of the beam that allows cutting close to the machine and faraway of the machine, even parallel to the ground!

Reinforced back end of the beam for taking support while moving the base machine.

NEW metal covers for hydraulic joints and valves!

NEW adjustable front sliding plates!

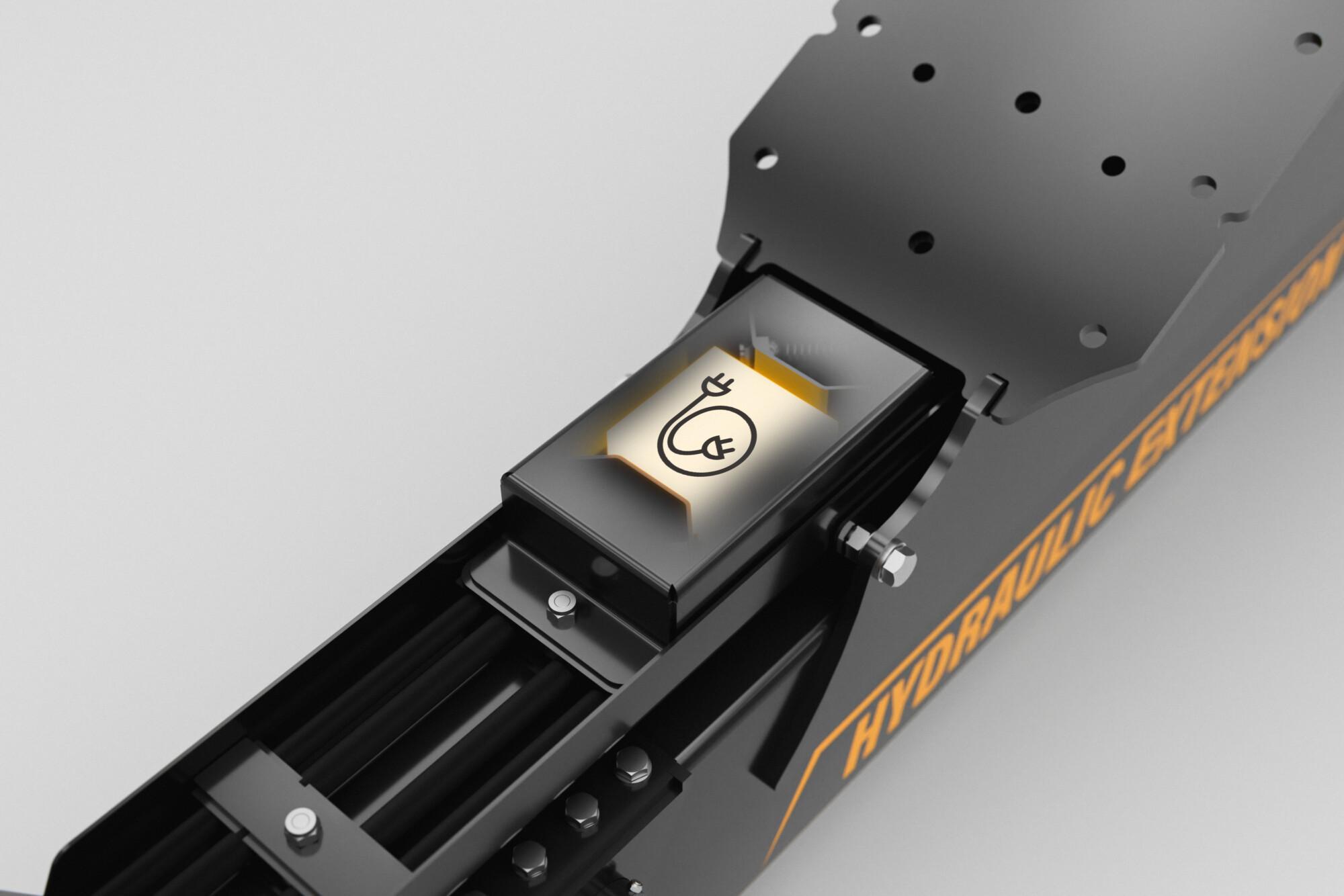

NEW maintenance hatch at the back of the beam for easier maintenance!

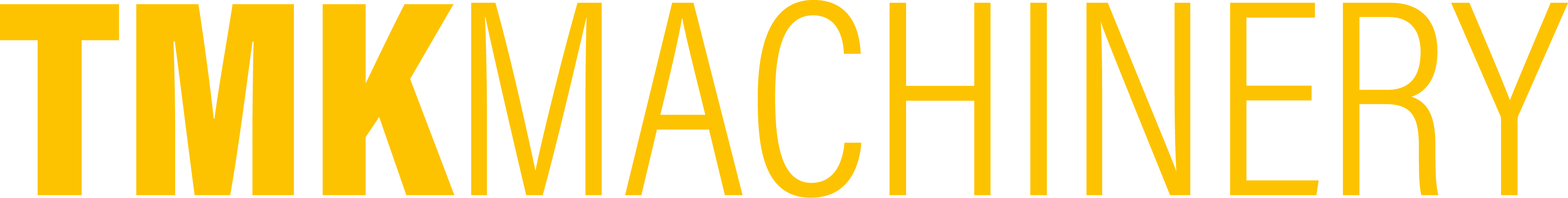

NEW easily accessible and protected electrical box!

Available for TMK 200*, TMK 250 and TMK 300.

*TMK 200 uses a lighter Gen1 version of the Hydraulic Extension so that it can be used with small base machines.

The TMK Tree Shear’s Adapter Plates are a key element of the shear’s adaptability.

We recommend that you always use a Adapter Plate for shear attachment instead of welding the plate directly to the back of the shear. The Adapter Plate makes it easy to transfer the shear from one machine to another. If you ever decide to part with your shear, resale will be much easier thanks to the Adapter Plate.

The TMK Tree Shear’s Splitting Blade makes your work easier when you have to split big tree trunks. When split, timber dries better, and the Splitting Blade enables you to do this while using the TMK Tree Shear.

The Splitting Blade is quick to attach to the shear with three bolts.

The Heel gives added stability and reliability when moving in terrain. It provides good support, no matter the size of the machine. The Heel attaches to the backside of the shear with bolts, offering a good point of support when moving around with the machine.

The Heel is specially designed for excavators, but it can be attached to other machines, too, for example to remove tree stumps. In a Solid Extension, the Heel is always pre-installed.

The TMK Tree Shear’s Fixed Tilt meet the needs of such market areas where tiltrotators are not common. The Fixed Tilt enables a comprehensive tilting angle of up to 180 degrees: 90 degrees to the right and 90 degrees to the left. This means that a tree trunk can be tilted to horizontal position. The Fixed Tilt is controlled with two cylinders, one on either side. This enables equal power and speed on both sides.

The Fixed Tilt enables the removal of large branches and problem trees in a controlled way. If your work includes cutting plenty of trees that have not grown straight or are difficult to reach, the Fixed Tilt is the ideal attachment. With the help of the Fixed Tilt, the machine can be moved even in rough terrain.

The Fixed Tilt is designed for TMK 300 and TMK 400 units, and it is connected to the back of the shear with bolts. The Fixed Tilt can be used either on its own hydraulic line or on the shear line using a 6/2 electric valve.

The R-series (Rotator) means that the tree shear is directly equipped with a rotator to make the operation more agile in challenging environments. The strengths of the R-series shears are its agility and efficiency and a wide range of other attachments.

With the Loader Extension we are fulfilling one of the most requested customer features: additional loading capabilities. The Loader Extension’s grapple arm is easy to control either directly from a separate hydraulic circuit available, or alternatively from the same hydraulic circuit in use of the Tree Shear with the help of an electric diverter valve. Grapple geometry has been designed so, that grabbing and handling large tree stacks is easy even in tight spaces.

But it doesn’t end there, you get much more than just loading capabilities with the Loader Extension! It gives extra reach for the Tree Shear and makes it possible to further utilize a tiltrotator and for example make cut behind trees and make piles on the sides without moving the machine. It also serves as a very sturdy heel that you can use to nudge rocks or trees that are in the way and support the machine when moving.

There are two versions of the Loader Extension: Solid and one with a tilt.

The solid is very useful if you just want to add the loading capabilities and get some extra reach like you would get with our Solid Extension. It is retrofittable to any existing TMK 300 or TMK 400 model.

If you want to go to the next level, you can choose the Loader Extension with a tilt. It unlocks a whole new level to your working, especially when used in conjunction with a tiltrotator. You can reach higher, further and closer with the shear being in optimal position for cutting and delimbing thanks to the geometry and the tilting action of the Loader Extension. Tilting motion happens with the help of a much smaller cylinder than the excavators own bucket cylinder, making it much quicker and more fuel efficient than using the whole boom structure of the excavator.

Note: Loader Extension with a tilt requires a new shear frame because of the different attaching method, consult your dealer to find a solution if you want to have one fitted to your existing shear.

The versatile cylinder options for main cylinders of the TMK Tree Shear allow you to adapt the shear to your existing machine, both in terms of cutting power and operating speed. Because of various cylinder options, the shear can be connected to just about any machine.

The same cylinder options are available for the TMK 200 and 300 models. Two cylinder options are available for the TMK 400 model.

Normal cylinder

This was used for the first tree shear. When the base machine can provide a pressure of 280–300 bar, the normal cylinder is a safe choice.

Bigger cylinder

When we exported our first tree shears, we received feedback that they were lacking in power. We learned the pressures used outside Finland were often lower, and the timber was harder. We added a large main cylinder to address the issue.

TMK Turbo is a patented cylinder consisting of a smaller cylinder inside a bigger one. The smaller cylinder is always activated first, and the bigger one only if there is not enough power. This arrangement harnesses the speed of the small cylinder and the power of the large cylinder. TMK Turbo will increase your work efficiency by up to 15%.

The HD cylinder is a powerhouse for small machines in particular. When a big tree needs to be cut with limited pressure, the HD cylinder is just what you need. It can operate efficiently at up to 180 bar, even with larger trees.

All what the base model TMK Tree Shear needs to function is one double-acting hydraulic circuit.

Our TMK Tree Shear has two ½” BSP standard quick couplers (inlet & outlet) on top of the frame where your machine’s hydraulic circuit will be hooked up into, feeding directly to the cutting cylinder on a standard model, or to our custom valve body on a model with attachments.

Adding attachments such as the Collector and Delimber do not necessarily require any additional hydraulics from your machine, as they can be easily installed and set up with our innovative and customer-oriented valve & installation kits.

By default, the electrical wiring kit or pressure-diversion valving is included in the price of the attachment, whereas gaining the fully wireless radio control with TMK Wireless Kit comes at extra cost, but is extremely useful in certain situations such as using the product with a tiltrotator or between multiple different machines.

Electrical Wiring Kit

This option is always included in the price of Collector or Delimber and is very simple, requiring our electrical wiring harness to be installed between the tree shear and the cabin by the user.

Only one electrical push button required / attachment for control. The electric push button is used when you want to drop the cut trees from the hold of the Collector or activate the Delimber around the tree.

TMK Wireless Kit

TMK Wireless Kit is the best option for tree shears installed under tilt rotators or usage between multiple host machines. Biggest benefit is to not to have any extra electrical cables in the harms way, but it definitely simplifies the first-hand installation process too

Receiver in the shear can be powered with either Makita or Milwaukee tool batteries and the transmitter can easily be used with our plug&play system, or directly wired to the excavator power supply and controller handles.

Direct Hydraulic Lines

If you wish to use either Collector or Delimber fully manually from a separate pump / hydraulic circuit available from your base machine, it is always possible.

With base machines and positioning of hydraulic outputs, quick couplers and hose lengths varying in each case: the customer is responsible for the hydraulic installation with this option.

Pressure Diversion

With pressure-diversion it is possible to have everything working without any electricity or additional hydraulics. It uses our innovative sequencing valve body and utilizes the pressure from your hydraulic system.

This control option is limited to models with only one attachment: meaning TMK Tree Shear models equipped only with a Collector, or only with a Delimber.

Contact us

Feel free to contact us and we will be happy to tell you more!

"(Required)" indicates required fields