Where to start?

As a member of TMK’s sales team I hear every day what clients want to know about our products. It is understandable that at first sight all the information about different tree shears can seem overwhelming. I am often asked what are the main points to consider when selecting the right product, and here I’ll give you a brief overview that will hopefully help you get started.

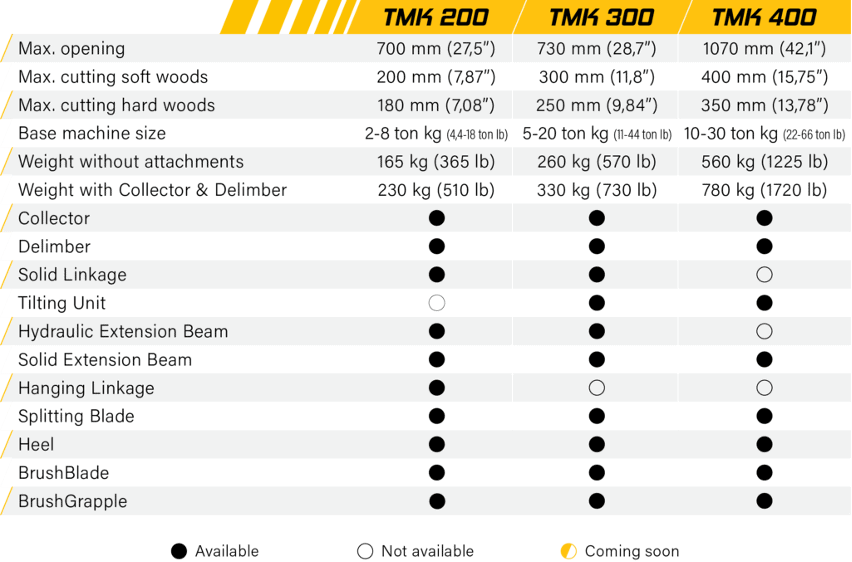

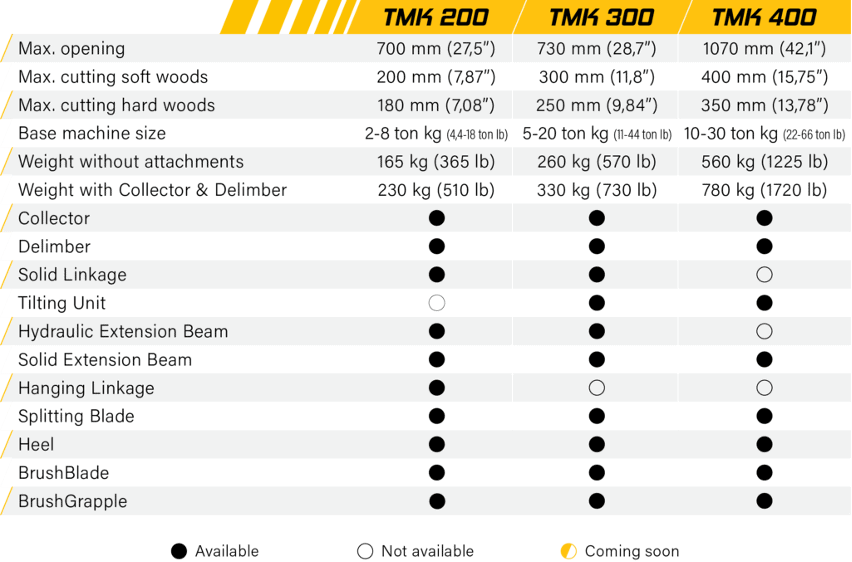

TMK product family includes 3 tree shear options: TMK 200, TMK 300 and TMK 400. Every shear is available with a BrushGrapple, which can cut soft twigs neatly and gets the work done during every season of the year. Furthermore, you only need one double-acting hydraulic circuit for cutting, delimbing and collecting the trees.

Our basic shear is a great choice for hobbyists with a limited budget. All the shears can also be customized with a variety of attachments to meet the professional and unique needs of every client. It is also possible to buy and retrofit attachments afterwards to already existing tree shears.

When choosing the best tree shear for your excavator, there are few aspects to consider. Let me go through the 4 most important ones to help you with your decision-making.

It’s all about size

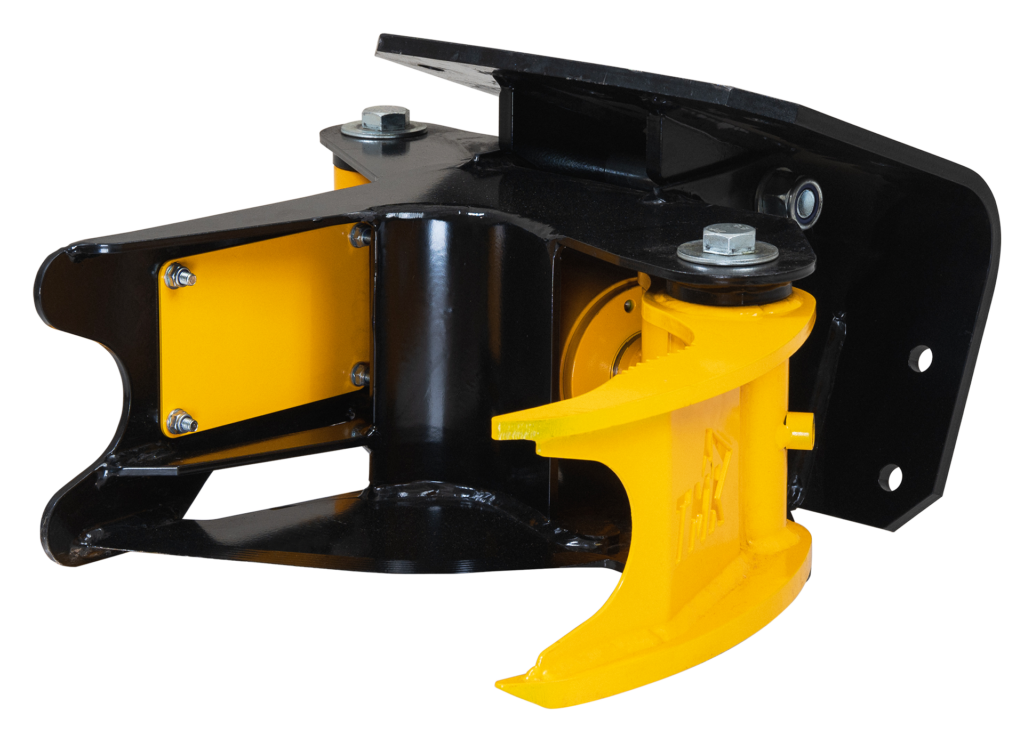

Every TMK Tree Shear is designed for a specific size. Our smallest tree shear TMK 200 is developed for the smaller machines. Its small size and precisely designed structure make this shear a good fit for tractor cranes, miniloaders and small excavators. This powerhouse, weighing only 165 kg, cuts hardwood up to 180 mm and softwood up to 200 mm quite comfortably.

TMK 300 is intended for machines weighing 5-20 tons. Its light weight (the basic shear weighs only 260 kg) and very durable capsular structure make this shear a good option for both large and small excavators. The shear, like all the other models as well, is manufactured from Hardox steel, which endures hard wearing. Thanks to the efficient blade, even a 300 mm tree can be cut neatly.

Our biggest and strongest shear TMK 400 was created for the large trees of Central Europe. ”Big Boy” fits to excavators from 10-30 tons. Shear opens respectively 1070mm and can cut trees up to 400mm. Still the basic shear with bracket only weighs 560 kg. With the help of the TMK 400 even heavy-duty excavators can keep earning also in the more

quiet winter months.

Cylinder options

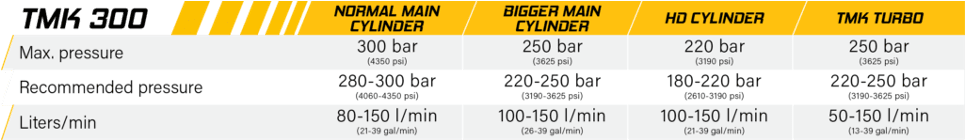

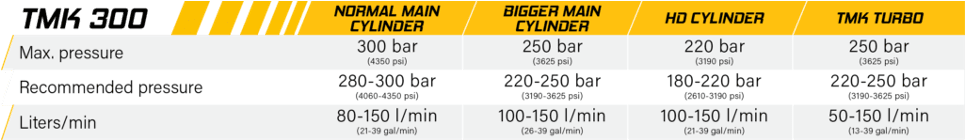

When you have the size of the shear figured out, it is time to consider the 4 different cylinder options TMK offers. The cylinder choice mostly depends on hydraulic flow and -pressure. In a nutshell, the more hydraulic flow the cylinder receives, the faster the cylinder speed. The higher the hydraulic pressure, the bigger the cutting capacity.

In Finland there are many excavators with tiltrotators that limit hydraulic pressure. This results in lower speed and cutting capacity of the shear. Often times this also affects the quality of work as smaller trees are left uncut to save time. The TMK Turbo cylinder developed and patented by TMK solves this problem. The small and fast 80 mm cylinder is great for smaller trees and when you run out of power, the bigger cylinder takes automatically over and finishes the job with the force of the 130 mm ram. The bigger cylinder can cut trees up to 300 mm.

Attachments are worth the investment

It is important to contemplate your professional needs and goals. Attachments make a big difference when it comes to efficiency.

The collector increases the productivity of the shear significantly. It works automatically with an open-close motion all the way to the point when you are ready to drop the bunch. Thanks to its high productivity, the collector is TMKs most popular attachment worldwide.

TMK also has the first easily controllable delimber on the market without expensive feeding systems. With the help of the delimber you can use the bottom part of a cut tree to make firewood as you are able to clear the branches from the tree. As the result of this process the tree also dries faster.

TMK’s solid extension beam (length about 1 m) was designed to give some extra reach and it works great with the tiltrotators to ensure that the sensitive hoses don’t get damaged in the bushes, but are kept in a safe distance from the branches. Therefore minimizing the damages. As the beam is attached with bolts, it can be taken off easily when not needed. The solid extension beam comes with the heel that gives you more support and reliability when moving in difficult terrain. It is especially helpful when crossing ditches and moving rocks or stumps out of the way.

If you want even more extra reach, it is possible to use the hydraulic extension beam (3,6 m).

These are only a few of the attachment options TMK offers. Check out our attachments page for more.

Controlling options

Lastly, depending on the attachments you choose, there are 2 different attachment controlling options: pressure diverted version or using electricity. If you opted for both the collector and the delimber, the attachments will use electricity. When using electricity, it is also possible to go wireless. For excavators with tiltrotators, this means there are no physical wires between the rotator and the excavator boom.

While I consider these 4 aspects the most crucial, this is only scratching the surface of what TMK products have to offer. For more information, contact a dealer closest to you.

-Rauno Kindma